Acid etched frosted glass, frosted glass and sandblasting glass are generic terms for decorative, translucent glass which obscures visibility, yet still allows diffuse light to filter through.

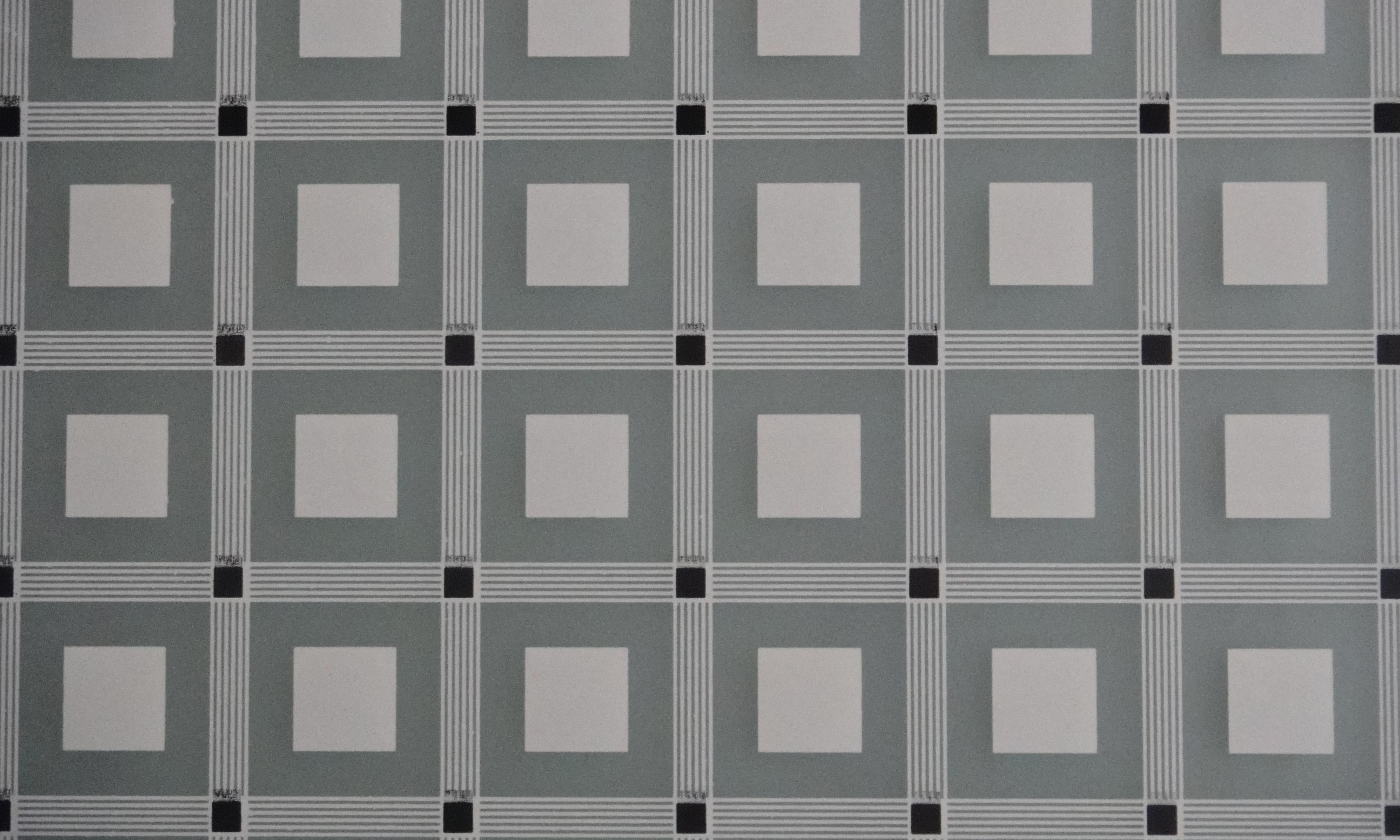

Etching describes the process of altering the glass surface to create a decorative effect, usually into artwork, a decorative pattern or lettering by hydrofluoric acid .

Frosting describes the process of changing the surface of the glass from transparent to translucent to create an opaque, cloudy look. This is usually achieved by use of alloy sand, steel brush and water.

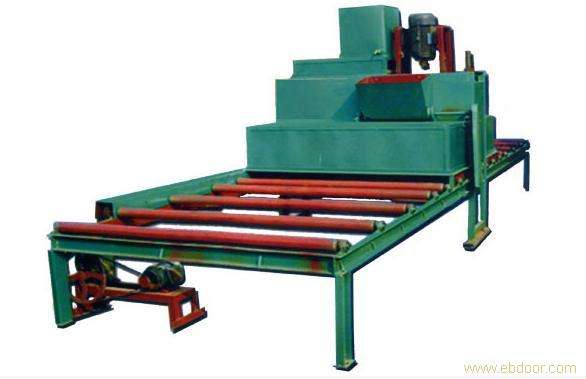

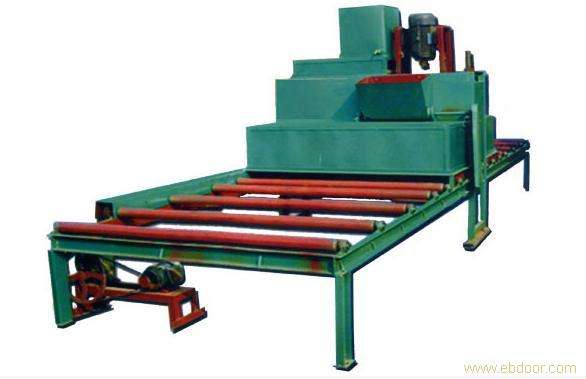

Sandblasting glass describe the process of changing the surface of the glass into santin finish. This is usually creat in special sandblasting machine by use the emery and high pressure.

All of the acid etched frosted glass, frosted glass and sandblasting glass have a wide range of practical uses in commercial settings, including interior and exterior doors, bathroom and kitchens, glass screens, glass partitions and glass balustrades.

How is Acid etched frosted glass, frosted glass and sandblasting glass produced?

Commercial etching is usually done in one of two ways: glass is either acid-etched or sandblasted. The method of chosen will depend on your project, but here is a quick summary of the two usual methods.

Acid-etched glass

Acid-etched glass, sometimes known as ‘French embossing’, is one of the oldest decorative glass techniques. Thousands of years ago, craftsmen discovered that heating fluorite, a deep green mineral, produced hydrofluoric acid which, when applied to glass, would erode the top layer of the glass and leave a frosted appearance.

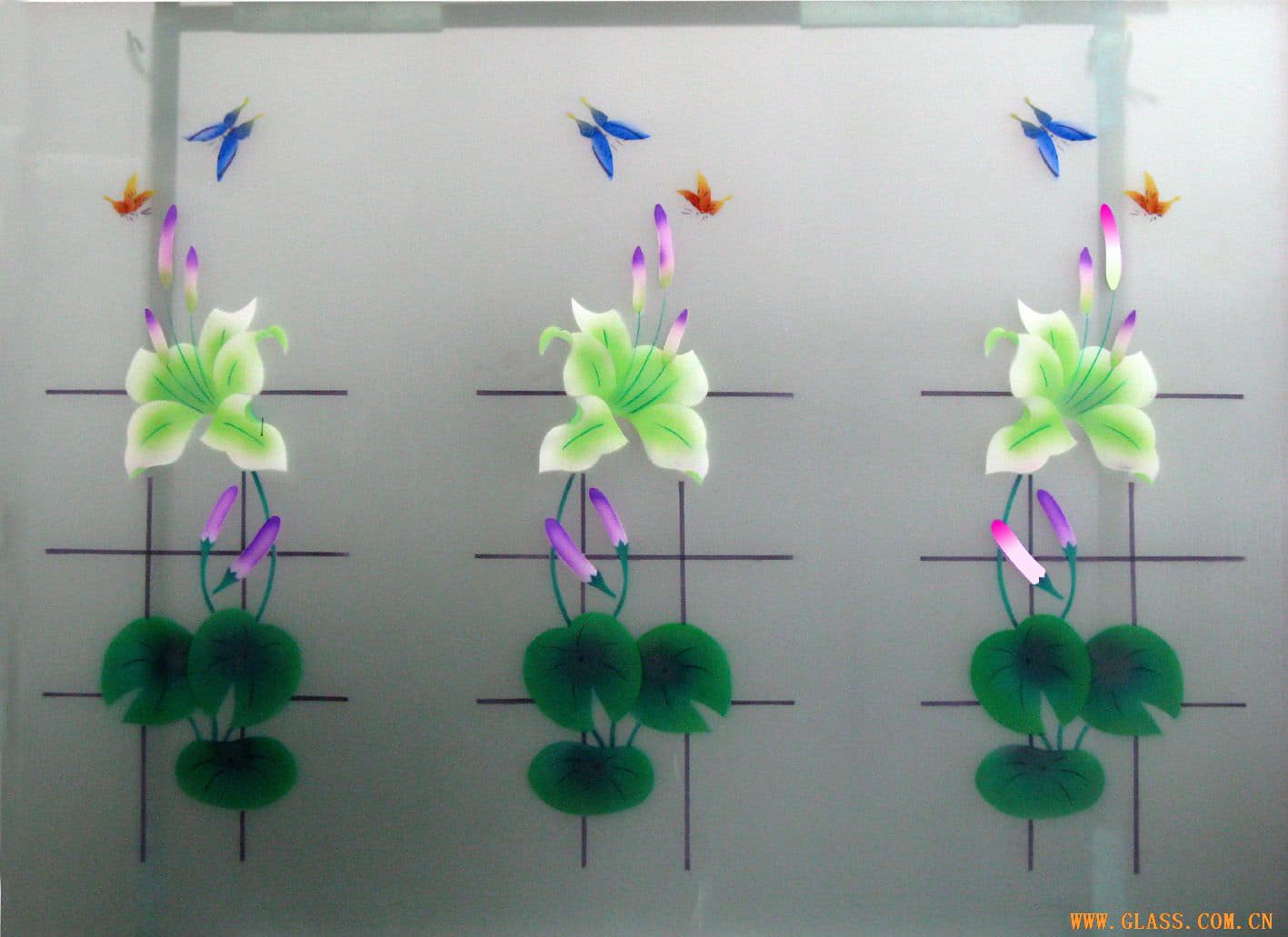

More recently, the process was used by the Victorians for decorating windows and doors in residential homes, pubs, restaurants and public areas. Decorative glass could be etched in different shades of white and embossed with gold and colour to create a luxurious and expensive feel.

Today, the process of acid-etching can be carefully controlled by using a mask to create artwork, intricate designs, lettering and patterns. Opacity levels can also be specified, and the patterns can also be back-painted to enhance the design.

Frosted Glass

Frosed glass is made by alloy sand, steel brush and water to make an unsmooth surface of on one side or both of the glass. This is an physical changes on the glass suface. Frosted Glass can produce about 5000 sqm in 8 hours and this is envirmenal production line. The shortage is that after long time use the dust will not so easily to clean as the acid etched frosted glass. But frosted glass price is much lower than acid frosted glass. The frosted glass can’t make desgin with frosted at same time, but we can coated design on frosted glass. But acid etched frosted glass and sandblasting glass all can make design togegher with the frosted effect.

Sandblasted glass

If you’re seeking fully-frosted glass or a plain, simple design for your project, commercial sandblasting may be the right choice for you.

Sandblasting can be carried out by machine or by hand, and involves blasting high-pressure sand particles at the glass, which erodes the surface of the glass.

Removal of minute amounts of glass in this way creates the characteristic rough surface and translucent quality of frosted glass.

The depth and intensity of sandblasting can also be controlled to provide different levels of opacity.

| Difference | Production material | Frosted with design | Changes | Price | Finish |

| Acid etched frosted glass | hydrofluoric acid | Avaliable | Chemical changes | Middle | Smooth |

| Frosted glass | alloy sand, steel brush and water | Not avaliable | physical changes | Lower | Unsmooth |

| Sandblasting glass | the emery and high pressure | Avaliable | physical changes | Higher | Unsmooth |

How to choose between acid-etched and sandblasted glass?

Acid-etched glass is the perfect choice for more complex, decorative designs. Acid-etching creates a distinctive, smooth, satin appearance which gives a true frosted look. The process leaves a permanent design which will not peel, chip or wear down over time.

Acid-etched glass also tends to be less prone to fingerprints than sandblasted glass, and is usually more economical than sandblasted glass.

Sandblasting tends to lead to a consistent, high-quality finish and is generally better-suited to larger projects, or for simple designs on window panels where more frosting is required. However, sandblasted glass tends to show up fingerprint marks more readily, so this is worth bearing in mind when considering where your frosted glass will be used.

Sandblasted glass is also generally more expensive than acid-etched glass, although lead times are usually faster.

How to order etched and frosted glass

When ordering etched and frosted glass, you will need to specify what level of opacity you need, where 0% is fully clear, and 100% is maximum opacity. You will be able to specify start and end points at any opacity range in between. For example, you may decide to fade a completely clear glass panel into a fully frosted effect, or simply opt for the entire panel to be frosted at a 10-20% opacity level.

Your choice will depend on the purpose of the glass, the level of privacy you need, and how much light needs to filter through.

Ginde Glass can work with you to plan and design your decorative glass and etched designs. Once your custom-made, scale drawings have been approved, the glass usually takes between 6 – 8 weeks to produce.

If you would like to see examples of where we has provided decorative glass in commercial settings, please click here.

Alternatively, if you would like any advice on choosing frosted or etched glass, contact our expert team today on +86 13931911140

Exterior Door Glass

Exterior Door Glass

Acid-etched glass, sometimes known as ‘French embossing’, is one of the oldest decorative glass techniques. Thousands of years ago, craftsmen discovered that heating fluorite, a deep green mineral, produced hydrofluoric acid which, when applied to glass, would erode the top layer of the glass and leave a frosted appearance.

Acid-etched glass, sometimes known as ‘French embossing’, is one of the oldest decorative glass techniques. Thousands of years ago, craftsmen discovered that heating fluorite, a deep green mineral, produced hydrofluoric acid which, when applied to glass, would erode the top layer of the glass and leave a frosted appearance. Frosed glass is made by alloy sand, steel brush and water to make an unsmooth surface of on one side or both of the glass. This is an physical changes on the glass suface. Frosted Glass can produce about 5000 sqm in 8 hours and this is envirmenal production line. The shortage is that after long time use the dust will not so easily to clean as the acid etched frosted glass. But frosted glass price is much lower than acid frosted glass. The frosted glass can’t make desgin with frosted at same time, but we can coated design on frosted glass. But acid etched frosted glass and sandblasting glass all can make design togegher with the frosted effect.

Frosed glass is made by alloy sand, steel brush and water to make an unsmooth surface of on one side or both of the glass. This is an physical changes on the glass suface. Frosted Glass can produce about 5000 sqm in 8 hours and this is envirmenal production line. The shortage is that after long time use the dust will not so easily to clean as the acid etched frosted glass. But frosted glass price is much lower than acid frosted glass. The frosted glass can’t make desgin with frosted at same time, but we can coated design on frosted glass. But acid etched frosted glass and sandblasting glass all can make design togegher with the frosted effect. If you’re seeking fully-frosted glass or a plain, simple design for your project, commercial sandblasting may be the right choice for you.

If you’re seeking fully-frosted glass or a plain, simple design for your project, commercial sandblasting may be the right choice for you.